OEM-grade spline couplings engineered for Indian and international pump brands.

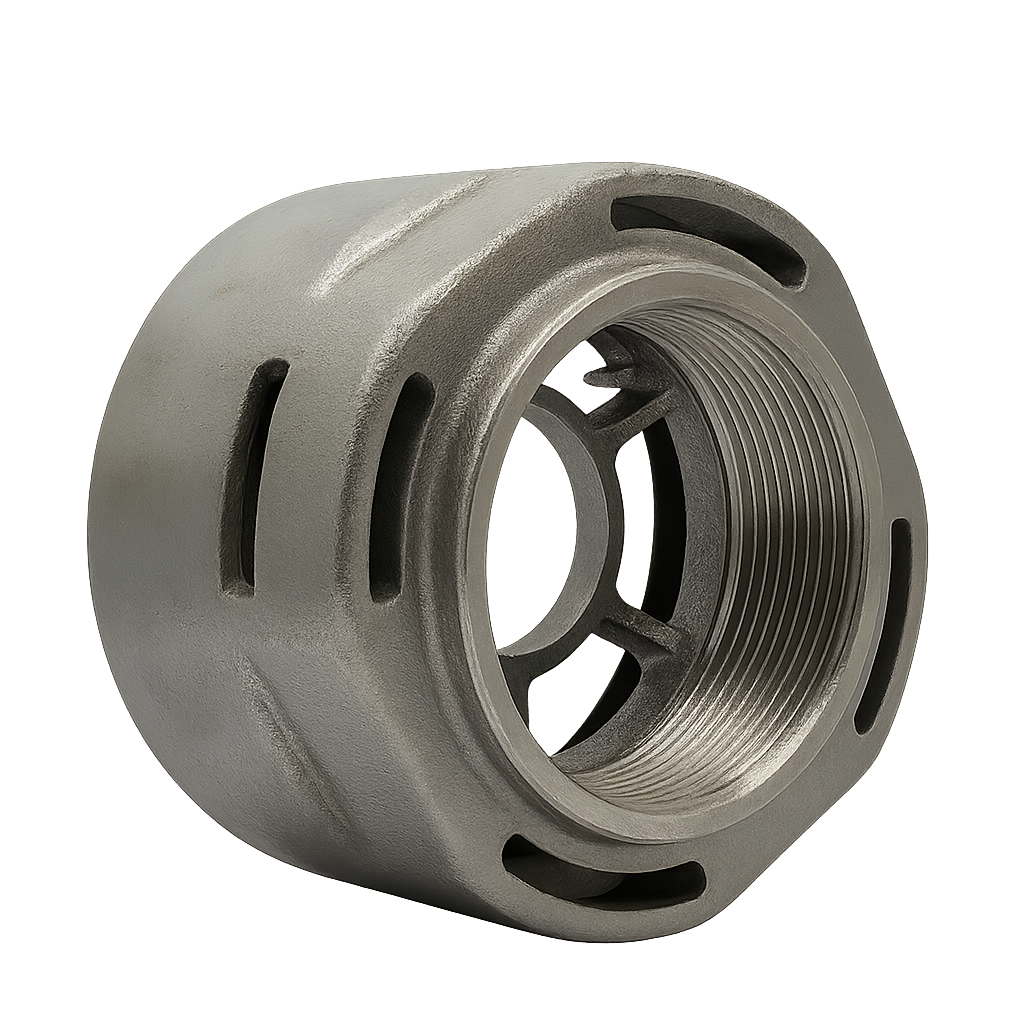

Sadguru Engineering designs and machines submersible pump spline coupling assemblies that transmit high torque while maintaining perfect shaft alignment. Our couplings are produced on CNC lathes with in-house broaching, splining and nitriding facilities so OEMs get consistent quality and short lead times.

Whether you require NEMA spline coupling designs, custom spline profiles or corrosion-resistant stainless steel builds for aggressive water chemistry, our engineering team collaborates directly with pump manufacturers to finalize drawings, tolerances and inspection plans.

Dedicated CNC turning, VMC and broaching lines for spline accuracy within ±0.01 mm.

Validated for 100–5000 Nm torque loads with metallurgical reports and hardness certificates.

Nitrided, black-oxide or passivated finishes to handle coastal, irrigation and industrial duty.

Answers for pump OEMs and maintenance engineers.

Most 6-inch submersible motors use a straight-sided or involute spline with 10–12 teeth. Share your drawing or the NEMA frame reference and we will match tooth depth, pitch diameter and engagement length exactly.

Yes, apart from EN-series carbon steel we supply stainless, duplex or bronze couplings for corrosive borewell and seawater projects, along with full lab reports.

Each coupling passes spline profile inspection, concentricity checks, hardness validation, magnetic particle testing (if required) and visual QC before packing.

We already ship to Middle East and African OEMs. Export-ready packing, HS code documents and material traceability are provided as standard.

Your Trusted Partner in Precision Manufacturing

Sadguru Engineering is a premier manufacturer of submersible pump parts, serving the industry with excellence for over 15 years. Our commitment to quality, precision, and customer satisfaction has made us a trusted name in the manufacturing sector.

Advanced manufacturing processes with CNC technology

Quality, Environment, and Safety certified

Reliable delivery schedules for all orders

Complete Range of Submersible Pump Components

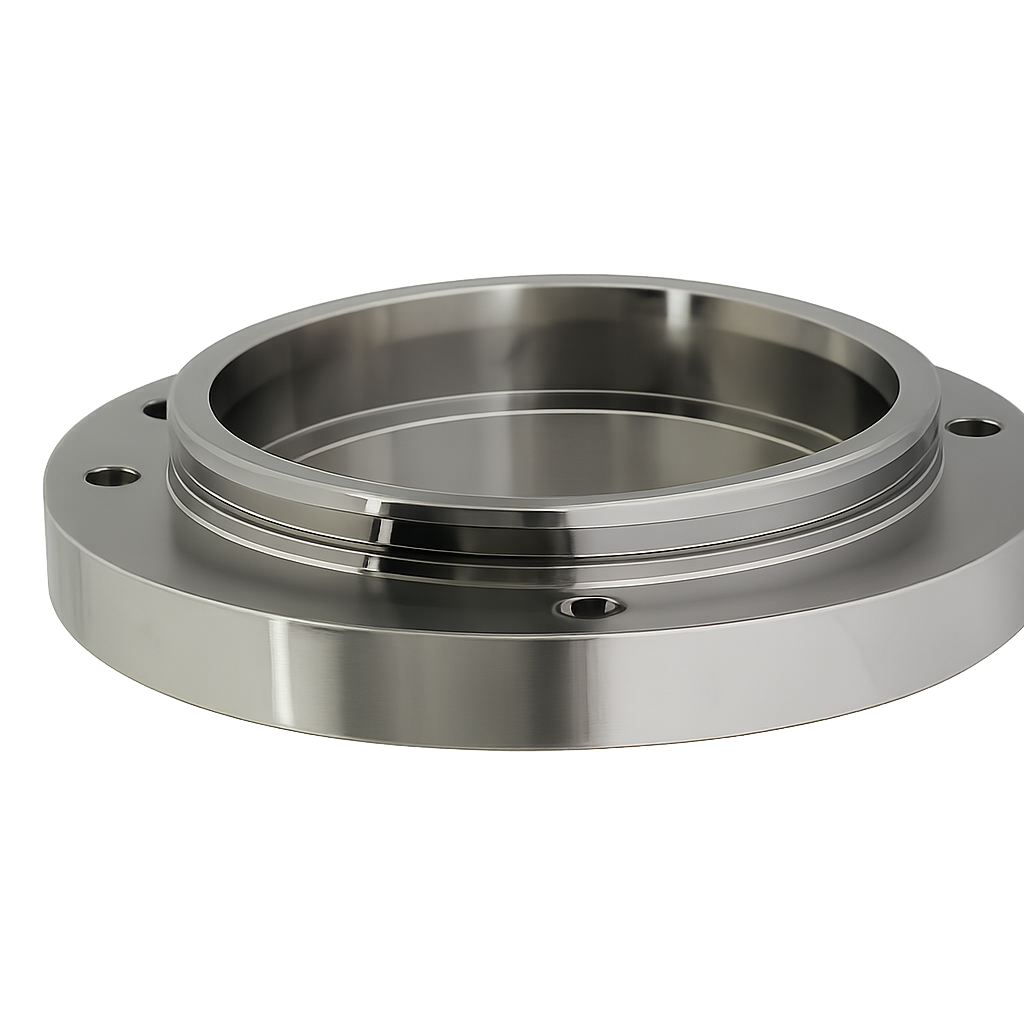

High-quality pump housing components manufactured with precision engineering for optimal performance and durability.

Learn More

Precision-engineered spline couplings designed for efficient power transmission and long service life.

Learn More

Standard NEMA couplings manufactured to exact specifications for reliable motor-pump connections.

Learn More

Durable bowl sleeves designed to withstand harsh operating conditions and provide optimal sealing.

Learn More

High-performance mechanical seals ensuring leak-free operation and extended pump life.

Learn More

Precision-engineered spline shafts designed for efficient power transmission and long service life in submersible pumps.

Learn MoreExcellence in Every Component

Advanced manufacturing technology and skilled engineering team ensuring superior product quality.

Optimized production processes for maximum efficiency and cost-effectiveness.

Custom manufacturing solutions tailored to meet specific customer requirements.

Working closely with customers to develop the best solutions for their needs.

Continuously improving processes and adopting latest manufacturing technologies.

Competitive pricing without compromising on quality and performance.

Environmentally conscious manufacturing processes and ISO 14001 certification.

Committed to ethical business practices and maintaining long-term relationships.

Contact us today for your submersible pump parts requirements. Get competitive quotes and expert technical support.