Premium submersible pump parts manufactured with precision and quality

We machine submersible pump spline coupling assemblies for leading borewell, dewatering and irrigation pump brands. Our in-house tool room allows us to deliver involute/straight splines with zero backlash, balanced torque transmission and corrosion resistance suited for harsh groundwater conditions.

Every coupling is produced in Rajkot with ISO 9001 quality systems, PPAP documentation and 100% inspection of spline profile, pitch diameter and runout. For OEMs, we offer co-engineering support to redesign couplings for higher torque, vibration reduction or NEMA compliance.

Reverse engineering, CAD validation and tolerance stack-up for legacy pump models.

Monthly output of 18,000+ couplings with CNC turning, grinding and broaching lines.

Full PPAP, IS/NEMA certs, material traceability and ultrasonic/MPI reports on request.

We manufacture high-quality components for submersible pumps with ISO 9001:2015 certification

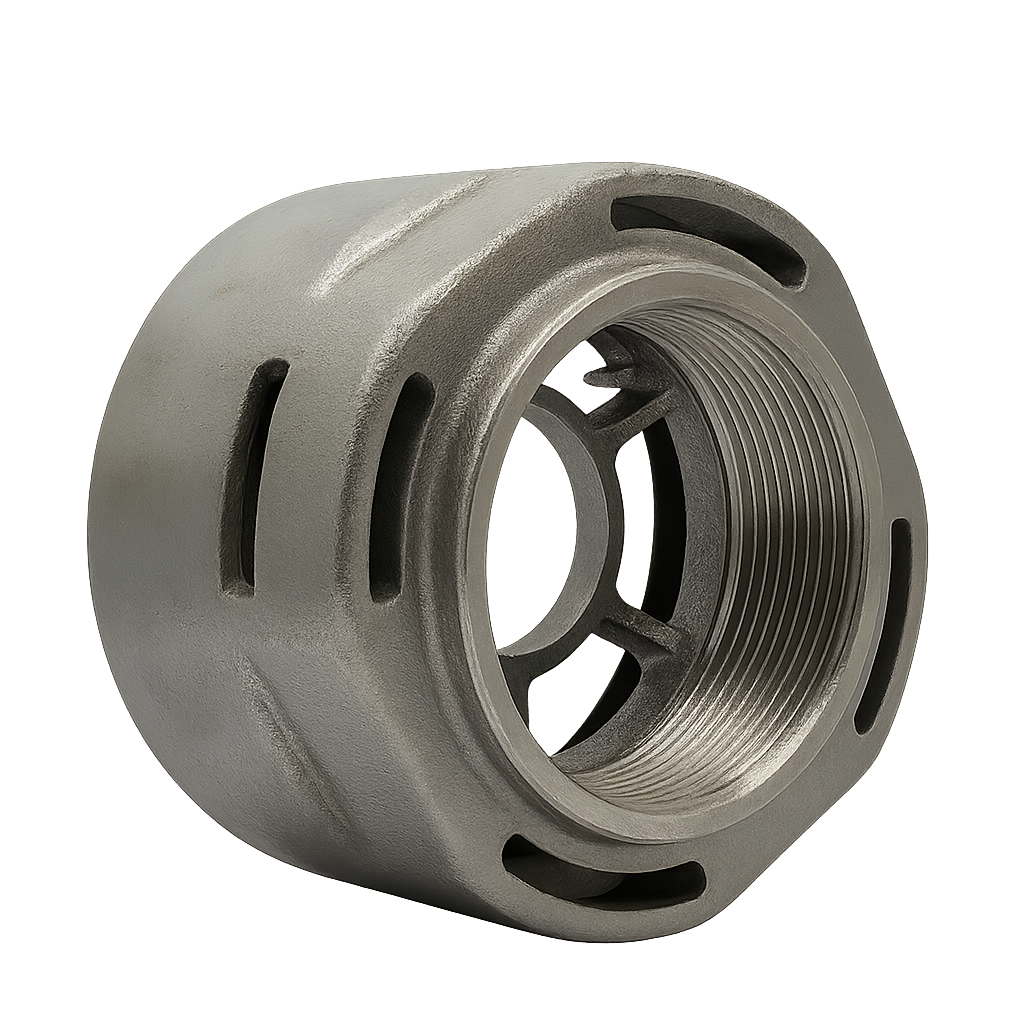

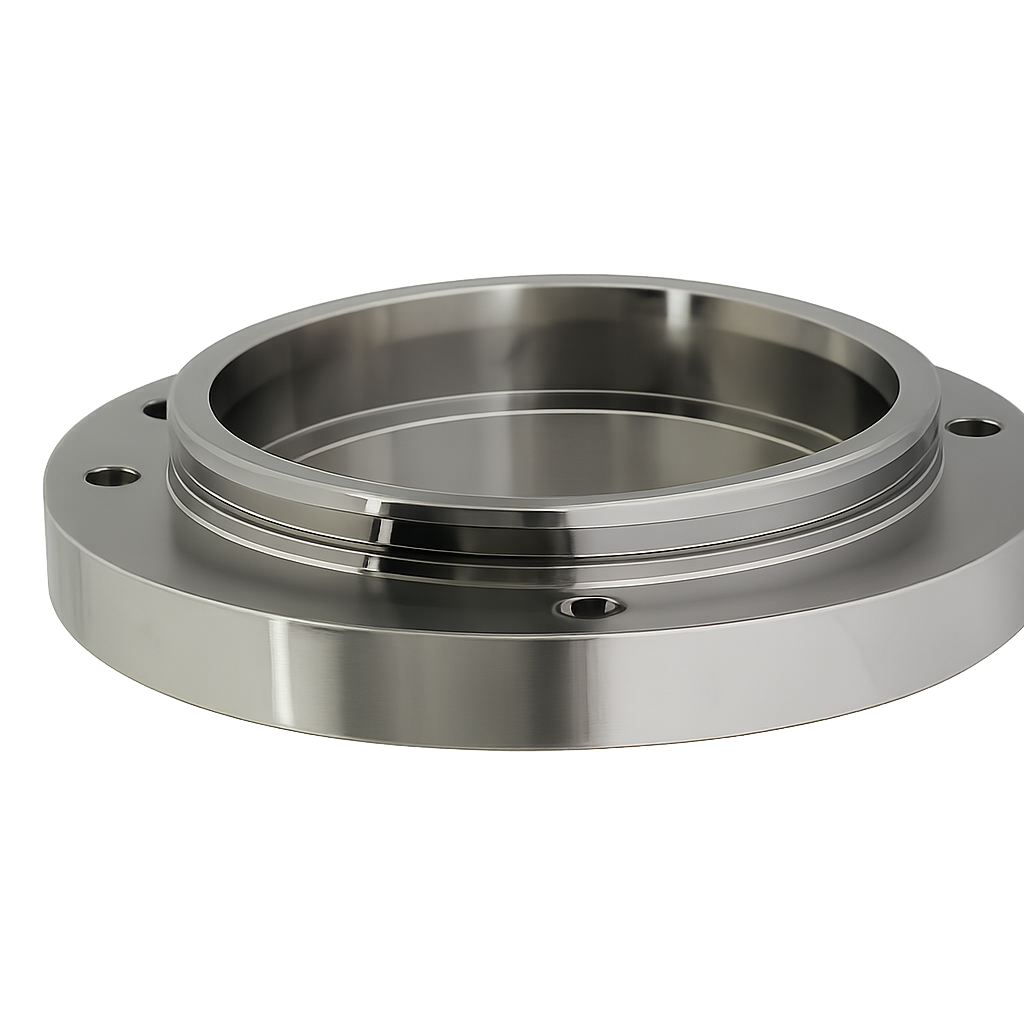

Precision-engineered pump housing components designed for optimal performance and durability in submersible pump applications.

Robust spline coupling systems that ensure reliable power transmission and alignment in submersible pump assemblies. Each coupling is CNC-machined, broached and nitrided in-house to achieve the zero-backlash fit that Indian borewell and export-grade OEMs demand.

Standard NEMA coupling solutions that provide secure motor-to-pump connections. We manufacture NEMA 4", 6", 8" and 10" frame spline couplings with precise tooth geometry to match Franklin, Bharat Bijlee, Lubi and other international motor brands.

Precision-machined bowl sleeves that provide optimal fit and performance for submersible pump impellers.

High-performance mechanical seals designed to prevent leakage and ensure reliable operation in submersible pump applications.

Precision-engineered spline shafts that provide reliable power transmission and alignment in submersible pump systems.

Every product undergoes rigorous quality control processes

ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certified manufacturing processes.

Comprehensive material testing and analysis to ensure optimal performance and durability.

Advanced measurement equipment for precise dimensional control and quality assurance.

Thorough final inspection and testing before dispatch to ensure customer satisfaction.

We can manufacture products according to your specific requirements and technical specifications.